2.1 Fan frequency conversion transformation energy saving principle

2.2 Water pump frequency conversion transformation energy-saving principle

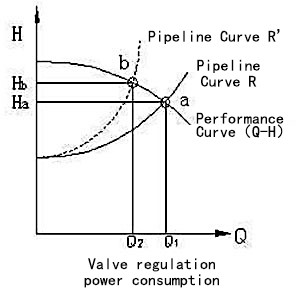

When the water pump is controlled by a valve, when the flow requirement is reduced from Q1 to Q2, the valve needs to be closed down. As the frictional resistance of the valve increases, the curve of the pipeline will move, the head will rise from Ha to Hb, and the operating point will move from point a to point b.

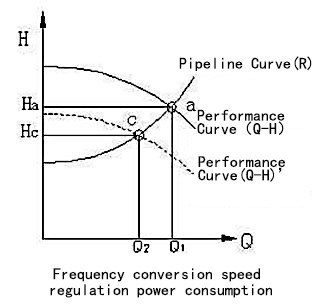

When the pump speed is controlled, the flow requirement is reduced from Q1 to Q2 because the resistance curve remains the same and the characteristics of the pump depend on the speed. If the speed is reduced, the performance curve will change, the operating point will move from point a to point c, and the head will drop from Ha to Hc.

Centrifugal pump characteristic curve formula

N=RQH/102η

In the formula: N- pump working condition shaft power (kW);

Q-the flow rate of the operating point (m³/s);

H-head of working condition point (m);

R- output medium unit volume weight (kg/m³);

η - the efficiency of the operating point (%);

The shaft power of the pump running at point b and the shaft power of the pump at point c can be calculated as:

Nb=RQ2Hb/102η

Nc=RQ2Hc/102η

The difference between the two is △N=Nc-Nb=R×Q2×(Hb-Hc) / 102η

When the valve is used to control the flow, the △N power is lost and wasted, and as the valve is continuously closed, this loss will also increase. If you don’t use the method of closing the valve, but just reduce the motor speed, in the case of running the same flow rate, the original power consumed by the valve will be completely avoided, and a better energy-saving effect can be achieved. This is the speed regulation of the water pump.

Principle of energy saving.

The basic principle of frequency conversion speed regulation

The basic principle of frequency conversion speed regulation is based on the speed relationship in the working principle of AC motors.

n-60 f (1-s) / p

In the formula, f-the power frequency of the water pump motor (Hz);

P-number of pole pairs of the motor;

From the above formula, it can be concluded that uniformly changing the power frequency f of the stator winding of the motor can smoothly change the synchronous speed of the motor. As the speed of the motor slows down, the shaft power will decrease accordingly, and the input power of the motor will also decrease accordingly. This is the energy-saving effect of water pump frequency conversion speed regulation.

Stay connected

Be the first to know about our new product launches, latest blog posts and more. The production base of Schorch Electric Co., Ltd. is located in Suining City, Sichuan Province. It adopts the advanced technologies and manufacturing techniques of Europe. The production technologies are advanced, stable and reliable.

The production base of Schorch Electric Co., Ltd. is located in Suining City, Sichuan Province. It adopts the advanced technologies and manufacturing techniques of Europe. The production technologies are advanced, stable and reliable.

Any question or request?

Click below, we’ll be happy to assist. Contact us